Jan 3, 2025

The Role of Plasma Technology in Manufacturing Custom Agriculture Tools

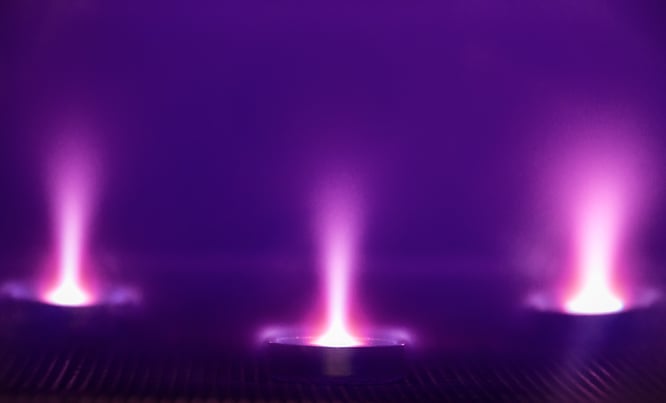

Image sourced from https://www.plasma.com/en/what-is-plasma/

Modern agriculture demands efficiency and precision. Farmers constantly seek ways to optimize their operations, and specialized tools play a crucial role in achieving this.

While mass-produced equipment serves many purposes, the diverse needs of contemporary farming often require custom solutions. Plasma technology, specifically arc cutting (PAC), offers a powerful and versatile method for manufacturing these custom tools.

This article explores the applications and benefits of plasma technology in creating agricultural tools tailored to specific needs. Let’s delve in and learn more!

The Need for Custom Tools in Agriculture

Modern agriculture is far from a one-size-fits-all endeavor. Farmers face a wide range of challenges depending on factors like soil type, climate, the specific crops they cultivate, and the terrain they work. This diversity creates a significant need for tools tailored to specific circumstances.

- Diverse Farming Practices: Methods like no-till, organic, and precision farming need special tools. They are vital for effective implementation. Standard, mass-produced equipment may not be suitable for these unique approaches.

- Varying Soil Conditions: Soil composition varies greatly, from heavy clay to sandy loam. Tools designed for one soil type may be ineffective or even damaging in another. Custom tools can be designed to work optimally with specific soil conditions, improving efficiency and minimizing soil compaction.

- Specialized Crops: The cultivation of niche or unique crops often demands specialized harvesting or planting equipment. Standard tools may not be designed to handle the specific size, shape, or fragility of these crops.

Traditional tool-making methods often struggle to meet these diverse needs efficiently. This is where modern manufacturing techniques like plasma technology offer a significant advantage.

Plasma Technology: A Versatile Tool for Custom Fabrication

Plasma technology, especially plasma arc cutting (PAC), is vital in modern fabrication. It offers a versatile and efficient way to create custom tools. The process involves creating an extremely hot, ionized gas, or plasma, which is directed at the workpiece.

The best plasma cutter can melt and remove material, creating a clean and precise cut. It works on various conductive materials, including steel, stainless steel, and aluminum. So, it is ideal for making agricultural tools.

The advantages of plasma cutting for tool manufacturing are numerous:

- Speed and Efficiency: Compared to traditional cutting methods, this type of cutting is significantly faster, allowing for rapid prototyping and production.

- Versatility: Plasma cutting can cut various materials and thicknesses. So, it is suitable for many agricultural tool uses.

- Complex Shapes: It can easily create complex shapes and contours, which are essential for manufacturing specialized tool components.

- Cost-Effectiveness: The equipment's cost matters. But plasma cutting is often faster, more precise, and more versatile. So, it usually has lower production costs than other methods, especially for custom or low-volume jobs.

Customizing Agricultural Tool Using Plasma

Plasma technology offers various applications in manufacturing and modifying agricultural tools. This enables farmers to optimize their equipment for specific needs.

- Tillage Equipment: Custom plowshares can be created using this method to match specific soil types. This improves soil turning and reduces soil compaction. Cultivator teeth and furrow openers can also be precisely cut to optimize seedbed preparation.

- Harvesting Equipment: Combine headers can be modified or repaired using plasma cutting. It ensures efficient harvesting of various crops. Custom picking mechanisms for delicate fruits or vegetables can be fabricated with precision.

- Planting Equipment: Seed drill modifications can be made to accommodate different seed sizes or spacing requirements. Custom planters can be designed for unique planting patterns or specialized crops.

- Repair and Modification: Broken parts of existing equipment can be quickly and efficiently repaired or replaced. We can adapt existing tools for new uses. This extends their lifespan and cuts the need for costly replacements.

These applications demonstrate the versatility of this technology in addressing the diverse needs of modern agriculture.

Other Applications of Plasma Technology

Plasma technology is vital to modern agriculture. It builds its infrastructure beyond just making tools. The precise cutting capabilities are invaluable in building greenhouses and vertical farms.

Controlled environment agriculture (CEA) systems need precise sizes and tight tolerances for their parts. This includes structural components, ventilation systems, and hydroponic or aquaponic setups. Plasma cutting ensures accurate cuts in steel, aluminum, and plastics used in framing, supports, and other critical elements.

This precision is essential for maximizing space utilization. It will ensure structural integrity and optimize environmental control within these sophisticated growing environments, contributing to efficient and sustainable food production.

Conclusion

Plasma technology has become essential for creating custom agricultural tools. Its precision, speed, and versatility offer significant advantages for farmers. From tillage to harvesting, plasma cutting enables efficient tool manufacturing and modification.

This technology improves productivity, reduces costs, and allows for greater adaptability to specific farming needs. Plasma technology will continue to play a vital role in the future of agriculture.