Aug 28, 2024

Mushroom Farming Thrives with Advanced Climate Control

Source: https://edition.cnn.com/2023/08/10/business/mushrooms-abu-dhabi-desert-below-farm-spc/index.html

August 28, 2024

Authors: Emily Newton, Niko Simos

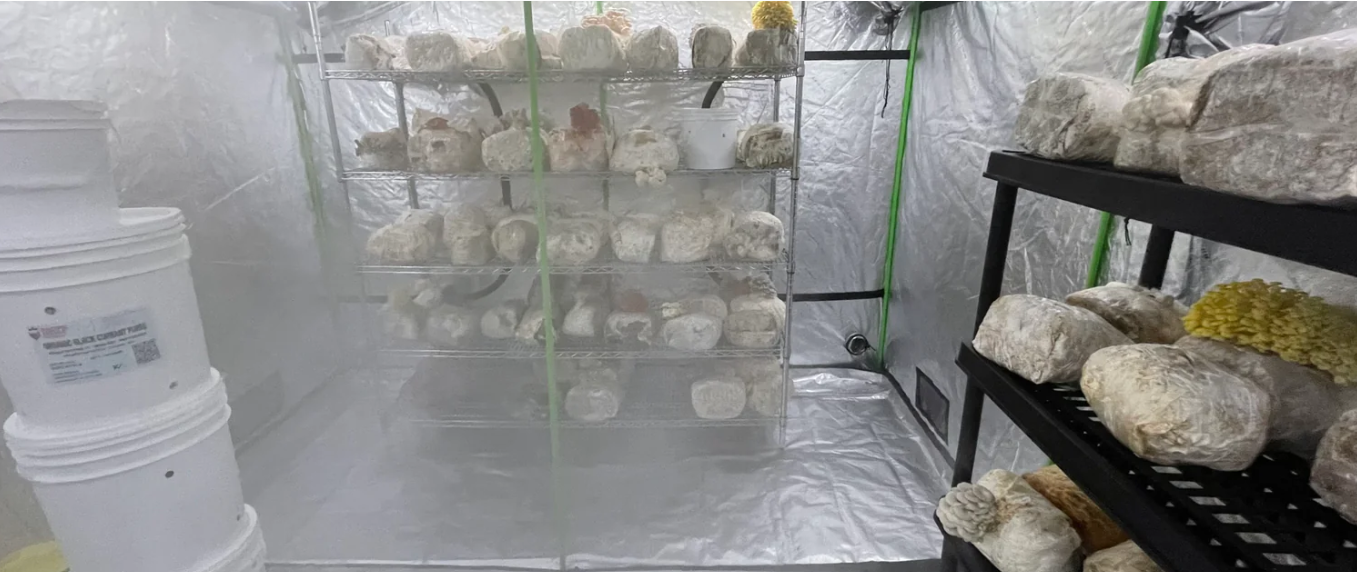

Mushrooms may be many beginner farmers’ entry into the agricultural world, with their accessibility, rapid growing speeds and DIY potential. However, mushroom cultivation operations have expanded into high-tech realms.

Advanced mushroom environment control is allowing growers to learn more about their products while boosting yields. Mushrooms are highly sensitive to environmental changes, and even slight fluctuations in temperature or humidity can affect their development and yield. Discover what this looks like when practiced by professionals and how to achieve a similar setup.

Tech Required for Advanced Mushroom Environment Control

As the mushroom farming industry advances, technology is playing an increasingly vital role in optimizing growing conditions. While experienced farmers can cultivate mushrooms in various environments, achieving consistent, high-quality yields requires precise control over the growing conditions. This is where automation and advanced climate control systems come into play, reducing labor demands while enhancing the accuracy of environmental management.

.jpg?width=650&height=650&name=Firefly%20Indoor%20high%20tech%20mushroom%20cultivation%2092078%20(1).jpg)

With nearly 90% of U.S. farms adopting AI by 2021, it's clear that data-driven decision-making is transforming agriculture. Mushroom farming is no exception. By leveraging automation and analytics, cultivators can fine-tune every aspect of the growing environment, from temperature and humidity to airflow and lighting. This not only boosts yields but also provides valuable insights into the optimal conditions for different mushroom species.

The following sections will delve into the key technologies that are driving this shift, exploring how farmers can implement these innovations to achieve optimal results in their mushroom cultivation efforts.

Climate Control Hubs

Next-generation technologies give farmers access to software and user interfaces to alter the most intricate climate details. The systems can respond to environmental conditions, automatically accounting for changes to maintain a nourishing climate.

Alternatively, growers can adjust them from any device with connectivity. This includes manipulating heating, cooling and ventilation, with possible connections to smart devices like thermostats. The data visibility keeps workers informed of what conditions the blooms are trying to flourish in.

Mushrooms thrive within a specific temperature range, which varies depending on the species and growth stage. For instance, during the spawning stage, the temperature needs to be warmer, typically around 75-80°F, to promote mycelium growth. As the mushrooms transition to the fruiting stage, a cooler environment, usually between 60-74°F, is required to encourage proper cap formation and fruiting. Maintaining consistent temperatures within these ranges ensures that mushrooms develop correctly and reach their full potential.

Temperature control also plays a role in preventing diseases and pests. Warmer temperatures can lead to the growth of harmful fungi or bacteria, while cooler temperatures may slow down mushroom growth or cause them to become dormant. Advanced climate control systems allow farmers to fine-tune temperatures with precision, ensuring optimal conditions throughout the entire growth cycle.

Humidity Oversight

Mushrooms are sensitive to moisture changes, so knowing the humidity is critical to keeping content. Advanced climate controls connect moisture detectors with dehumidifiers, whether on walls or in the ground. Then, these systems trigger if metrics hit a programmed threshold. This prevents green and gray mold growth from spawning, keeping fungi as healthy as possible.

Mushrooms require high humidity levels, typically between 85-95%, to stay hydrated and maintain their structure. Insufficient humidity can lead to dried-out caps, reduced yields, and poor-quality mushrooms. On the other hand, excessive humidity can create a breeding ground for molds and bacteria, potentially ruining the crop.

Advanced climate control systems monitor humidity levels in real-time and automatically adjust them as needed. These systems often include dehumidifiers and moisture sensors that work together to maintain the ideal humidity. This not only supports healthy mushroom growth but also reduces the risk of diseases like Dry Bubble disease or contamination from harmful molds such as penicillium.

Airflow Management Tools

Mushroom cultivation requires a delicate balance of airflow to maintain the right level of moisture while ensuring fresh, clean air circulates through the growing environment. Proper airflow is crucial because mushrooms need consistent oxygen levels to thrive, but too much air movement can dry out their caps, leading to poor growth and reduced quality. To achieve this balance, advanced climate control systems often integrate fans, blowers, and filters specifically designed to manage air circulation. These components work together to gently move air throughout the growing space, ensuring that the mushrooms receive the oxygen they need without compromising moisture levels.

The fans and blowers are typically equipped with variable speed controls, allowing farmers to adjust the airflow based on the specific needs of the mushrooms at different growth stages. Additionally, high-efficiency particulate air (HEPA) filters are used to remove impurities, such as dust, spores, and other contaminants, from the incoming air. This filtration is vital for preventing the introduction of pathogens that could lead to crop contamination or disease outbreaks. By maintaining a clean and controlled air environment, farmers can significantly reduce the risk of mold growth, improve mushroom health, and ultimately increase the yield and quality of their crops..

Carbon Dioxide Monitoring

Carbon management is critical for yields but also environmental awareness. High carbon levels could lower yields by stunting mycelium, harming the fruiting process. The gases mushrooms exchange as part of their cycle are critical to balance, and insufficient carbon oversight could disrupt this, too. This is why air quality is so critical to manage.

Sustainability tracking is also becoming more widespread across agriculture, including independent operations. Keeping an eye on greenhouse gas emissions to reduce impact has never been a higher priority. Farmers can achieve more environmentally friendly operations and improved air quality by installing air compressors for enhanced aeration. Oil-free compressors only use 18% of their maximum horsepower compared to conventional versions, saving on fuel and electricity.

Environmental Analysis

This contributes to the wider umbrella of environmental analysis. Control hubs collect data over time with Internet of Things (IoT) integration capabilities. The sensors are data loggers showing farmers trends and projections based on typical conditions. These may sync with other climate control software — such as HVAC applications — to send alerts and notifications to growers when anomalies appear or preventive maintenance is required.

Advanced Lighting Systems

LED grow lights support mushrooms when outdoor conditions may not be reliable enough due to cloud cover or otherwise. Workers can program the lights to simulate optimal light cycles based on the species without emitting too much heat to influence temperatures.

Insulation

Indoor mushroom cultivation requires robust insulation to make any other climate control technology effective. Otherwise, environmental conditions compromise integrity. Thermal insulation panels are an option to reduce heat loss and prevent gain.

This prevents unnecessary energy expenditure from having machinery work overtime to compensate for condition shifts. There are even renewable mycelium-based insulation panels entering popularity because of their low carbon footprint and carbon sequestration potential.

Effects on Mushroom Cultivation and Health

While investing in the equipment may not seem immediately worth it, the returns on investment are notable. This is most apparent in the crop’s well-being.

The optimized temperature regulation maintains the climate at optimal conditions at all times. In outdoor environments, fungi are at the whim of the sun. Now, technology is in a place to foster its best fruiting conditions at all times, which has never been a phenomenon before. With climate control, the system knows the growth stage of the mycelium and adjusts to these general metrics accordingly:

- Prep and spawning: Around 75-80 degrees Fahrenheit, 90% humidity and carbon dioxide concentrations at more than 5,000 parts per million

- Mushroom bed and initiation: Between 60-74 degrees Fahrenheit, 95% humidity and carbon dioxide concentrations at more than 2,000 parts per million

- Harvesting: Around 65 degrees Fahrenheit, 90% humidity and carbon dioxide concentrations at more than 1,000 parts per million

It also prevents the crops from getting sick and spreading illness to the rest of the yield. In particular, white button mushrooms could suffer Dry Bubble disease that deforms growth. High humidity causes the affected spores to have a sticky quality, and airflow spreads them to healthy mushrooms.

Advanced controls could also prevent penicillium growth, which is hazardous to mushrooms and humans. This mold could harm the farm’s stability in more ways than one. First, it could cause crop spoilage. Then, it could make farmers ill, causing potential negligence and further output losses.

Instead of spending time and resources rehabilitating a potentially lost crop, mushroom farmers can invest their energy into learning how to optimize systems further to increase yield and expand into new business verticals.

How to Create an Advanced Mushroom Growing System

Mushroom farmers should employ these steps, knowing the equipment and advantages associated with them.

1. Design the Climate Control Setup

Farmers must design environmental setups based on the specific species for the best results. Layout planning should support the various microenvironments for each variety, collecting similar needs in a suitable location. This may vary across the growing complex, including the fruiting, inoculation, packing and shipping rooms.

2. Invest in Technology

Determine what the most influential and hard-to-manage metrics are for the species, and prioritize budgeting for these devices the most. Farmers can acquire more equipment to sync with other systems later, making climate control even more comprehensive as its capabilities expand. This includes the aforementioned dehumidifiers, carbon dioxide sensors, software and more, but it could also include fixtures like solar panels and influencers for energy management.

3. Install and Configure Systems

Position sensors, fans and other equipment in accessible, sensible locations for on-site management and mushroom health. It may take time for the technology to work at peak performance, as it needs to acclimate and learn about the conditions before refining its settings. Over time, farmers will monitor and adjust conditions to be even more precise as familiarity with the climate control systems grows.

The Future of Mushroom Cultivation

Advanced climate control is the next era of mushroom growing. Increasing yields is critical, especially because their usefulness is extending far outside the food industry. Sectors want to turn them into sustainable consumer products or build infrastructure using their strong bonds. Demand will skyrocket, and mushroom growers must be prepared to meet this by fostering the ideal setting.

Emily Newton is a science and agriculture writer. She is also the Editor-in-Chief of Revolutionized, an online magazine exploring science and industry. When she isn’t writing, Emily enjoys going for walks or camping under the stars.