Jun 22, 2021

Improving Energy Consumption & Wastage In Food Supply Chains

.png)

Editor’s Note: this is an investigative article from Agritecture’s Systems Engineer, Alberto López, and Agritecture’s former business development intern, Meredith Harris, on the impacts of reducing the length of a generalized food supply chain on energy use and waste production distribution. This is the second article of a two-part series, read the first part here.

Consumers Play The Biggest Role

Given that 35% of household food waste is avoidable, a considerable contribution to food waste minimization can be from consumers themselves. In the UK, it is estimated that ~19% of all food is post-purchase waste, of which 12% is considered avoidable.

According to the European Commission, food waste can be avoided by correctly planning shopping, checking expiry dates, and storing food properly. Here, personal eating habits are important too. Consumers looking to reduce their ‘foodprint’ can do so by (1) reducing meat consumption, especially red meat, (2) buying locally and seasonally, avoiding air-transported food, (3) reducing post-purchase food waste, and (4) opting for organic food.

Additionally, changing your cooking methods could lower energy usage.

Although seemingly simple, these changes will drastically help us make use of every last bit of food produced. The following tips have been found to be able to decrease energy consumption by up to 50%: (1) simmering or steaming rather than boiling, (2) using the residual heat in electric appliances, and (3) properly using kitchen tools (using properly sized and insulated pans).

Resource flows in agri-food systems, chart sourced from FUSIONS

Innovating In Production

Food loss and waste occurs at different steps of the supply chain depending upon the size of the agricultural operation and system in use. Social innovation and reshaping resource flows in agri-food systems is important for reducing food loss.

Reshaping Processing & Distribution To Limit Waste

In-vehicle refrigeration systems are essential to maintaining produce quality whilst in transit. According to energy conservation and management reports, systems based on the vapour compression refrigeration cycle, the most common ones, tend to be oversized to provide abundant operational margin. Large portions of the thermal energy in the Diesel exhaust could be recovered and be used to operate a thermally-driven refrigeration system (e.g. absorption cooling systems, ejector systems, thermo-acoustic refrigerators) and/or for power generation using thermo-electrics or turbo-generators.

To investigate energy usage in the last trip between shop to consumer tables, this team studied 2,570 retail food stores of diverse sizes, from convenience stores to hypermarkets in the United Kingdom. According to their analysis, energy consumption linked to food chilling and refrigeration largely dominates (up to 60 %) in small shops (below 1 400 m2), while in larger shops and hypermarkets lighting, heating and other appliances absorb most of the energy. For this reason, the choice of appropriate refrigeration technologies, and the especially adequate design of food display cabinets are among the most promising and feasible energy-saving interventions in food shops.

.png)

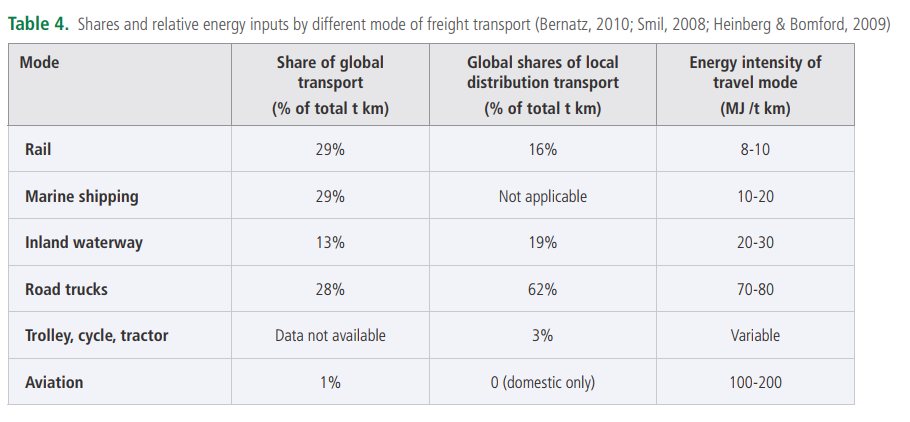

Shares and relative energy inputs by different mode of freight transport, sourced from FAO

What About Transportation?

Decreasing the overall distance travelled by food and food precursors is another way of minimising the amount of energy embedded in food products by transportation. Research is currently focusing on two aspects: optimising transport supply and decreasing transport demand.

*Caption: Shares and relative energy inputs by different mode of freight transport, sourced from FAO

Authors of a report in 2012 studied ‘short’ and ‘long’ food supply chains in Southern France, focusing on the transport from farm gate to consumers’ tables. On the case of shopping by car, the length of the round trip between consumers’ houses and the shops is currently averaged at 30 km in Europe. The industrialisation of the food sector has reinforced this habit by increasing the number of out-of-town shopping centres, which have replaced small local shops. The frequency of shopping trips and the distance travelled to purchase foodstuffs has increased in the last decades, thus imposing further energy consumption. Trips by consumers to purchase food can account for an additional 1 to 4 MJ of vehicle energy inputs per kg of food purchased.

What About Packaging?

The last point of discussion is packaging. The materials used to wrap and protect food are responsible for 10.7% of the embodied energy in the EU food consumption.

Improved packaging sustainability may seem complicated and far-reaching but, unlike many would think, it does not need to be achieved at the expense of quality. Moreover, good and long lasting packaging is an essential tool in minimising food waste and improving food durability, thus decreasing the overall energy consumption.

A relatively new field of research involves intelligent food packaging technology. This is packaging that is able to monitor and communicate information about the quality state of the packed food. This would allow optimal food consumption and minimise food waste and its related energy waste.

To figure out ways in which to lower your business’ energy consumption and food loss, request a proposal from Agritecture’s consulting team today. We can additionally help you figure out how to make your business more sustainable overall.

Want to learn more about energy considerations in CEA? Join us for this webinar!

About The Author

Alberto advises on optimization of operation and energy performance of greenhouses and CEA facilities. He has obtained hands-on experience in the operation, design, and construction of vertical farms while living in Europe.

Expertise: climate control strategies, resource analysis, technology assessment