Jun 16, 2021

Prevent Waste At Each Level Of Your CEA Operation

Editor’s Note: This is an investigative article from Agritecture’s Systems Engineer, Alberto López, and Agritecture’s former business development intern, Meredith Harris, on the impacts of reducing the length of a generalized food supply chain on energy use and waste production distribution. This is the first article of a two-part series.

The recent global reckoning of food security has sparked an increase in investment in local supply chains. The problems caused by disruption in the channels of distribution of raw materials, agricultural equipment, and finished products revealed the advantages of small, localized production chains.

It is safe to assume that there are many benefits to reducing the steps in a supply chain, such as the reduction of waste and increased efficiency of the process. However, it is important to understand where these potential changes can cause a significant impact in the supply chain.

This creates an interesting question: How does reducing the length of a generalized food supply chain impact efficiency and waste production?

To answer this question (and define the scope of research), the agricultural supply chain is understood to have the following steps: production, processing, distribution, and consumption. A brief overview of the energy use and waste production for each step is provided, which will give an understanding on where changes can be made.

Food waste

Food loss and waste along the supply chain, graph sourced from MEED’s Investing in Food Security report

A third of food produced, or 1.6 billion tons, is lost or wasted annually. This is equivalent to $1.2 trillion, and is estimated to continue growing.

As it turns out, households produce the largest proportion of food waste and generate predominantly avoidable food waste. The manufacturing sector is responsible for the next largest proportion of food waste but this is predominantly composed of inedible food waste. It has been estimated that in 2007 the energy embedded in the 27% share of edible food lost in the USA was equivalent to 2% of the annual energy consumption in the USA in the same year.

Production

According to FAO, in the North American food supply chain, 30% of food waste occurs in the production and harvesting stage.

In terms of crop growth success, in contrast to CEA-grown crops, soil-grown plants require the application of pesticides, which can cause harm to both human and environmental health. Additionally, they are susceptible to unanticipated weather events that may cause disruptions to the growing cycle. The reduction of both pesticide-related and weather risks within the localized CEA supply chain ensures greater success in crop growth, and thus less crop and energy loss.

According to Fertilizers Europe, the production of fertilizers slowly adds to this energy usage, varying from 0.2-14 MJ/kg (nitrogen-based fertilisers commonly require 10-14 MJ/kg). As a general rule, farming with biological inputs appears to be significantly better from the energy perspective, whilst high-quality proteins provided by livestock come at the cost of a much higher energy embodied. This is because animal feed accounts for 70-90% of the total energy embedded in the raw livestock products.

Processing

Share of electricity consumed by cross-cutting technologies in the food sector, graph sourced from Fabio Monforti

The greatest waste contributions occur in the processing phase in industrialized regions due to quality inspections.

According to FAO, the total amount of energy needed for processing and packaging is estimated to be between 50-100 MJ per kg of total retail food product. This includes energy for heating, cooling, and electricity, and is around three times the direct energy consumed behind the farm gate.

Moving to a process analysis, cooling and freezing account for about 30% of electricity consumption in the food industry, a relatively high share if compared with other industrial sectors.

Distribution

.png)

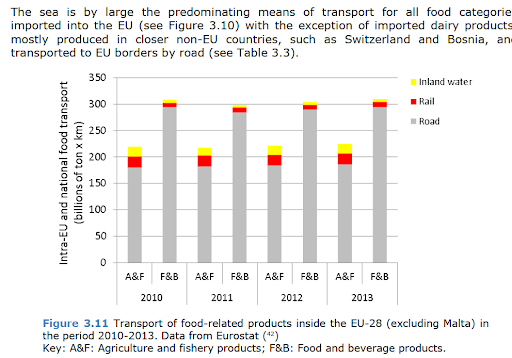

Transport of food-related products inside the EU-28 in the period 2010-2013, graph sourced from Fabio Monforti

The improper or incorrect storage and distribution of agricultural products can put crops at risk of infestation by fungi, insects and small mammals. Temperature-controlled vehicles play a large role in quality control, and become a major factor in terms of product wastage.

Another important element of energy usage in the food transformation industry is transport and logistics, accounting for 9.4% of energy embedded in food consumed in EU-27 in 2013. As far as the means of transportation is concerned, 83 % of the food and food precursors imported into the EU in 2013 had travelled by sea, 10% by road, 2% by rail and 1% or less by air and inland water.

Consumption

Post-consumer food waste contributes to the largest portion of losses in affluent populations. In the EU, even if generally managed in a safer way, food cooking and domestic conservation accounted for 13% of the energy embodied in 2013.

In terms of appliances, refrigerators, freezers, and combined fridge-freezers have been getting larger and more sophisticated in recent years. Larger models mean a greater energy consumption, and this trend towards large appliances is threatening to cancel out any savings achieved through greater efficiency (this is called the ‘rebound effect’). The most recent available data from the European Commission estimates an annual European electricity consumption by these products of 122 TWh in 2005, corresponding to 56 million tonnes of CO2e, which is comparable to the emissions produced annually by 24 million cars.

Where Do We Go From Here?

Stating problems without solutions is fruitless. Stay tuned for part 2 of this series on the energy usage and waste production distribution of a generalized food supply chain. This second article will dive into recommendations for reducing food waste and energy usage.

Want to learn more about energy considerations in CEA? Watch this webinar! You’ll have the opportunity to learn more about the industry’s energy consumption from Agritecture’s Systems Engineer, Alberto López, develop industry relations, and identify the knowledge gaps that can help your business tackle this challenge and become more energy-efficient and climate-positive.

About The Author

Alberto advises on optimization of operation and energy performance of greenhouses and CEA facilities. He has obtained hands-on experience in the operation, design, and construction of vertical farms while living in Europe.

Expertise: climate control strategies, resource analysis, technology assessment